Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How to Repair Hairline Cracks in Concrete?

Hairline cracks in concrete (typically 0.05–0.2 mm wide) are common but can lead to long-term durability issues if left untreated. This article covers how to assess, repair, and prevent these microcracks effectively.

Width: 0.05–0.2 mm (barely visible, similar to a human hair).

Depth: Usually surface-level (<10 mm), but some may extend deeper.

Common Causes:

Plastic shrinkage (during curing)

Thermal contraction

Minor settlement

✔ Repair if:

Located in load-bearing areas (beams, columns, slabs).

Exposed to water, chemicals, or freeze-thaw cycles.

Showing rust stains (indicating rebar corrosion).

✖ May not need repair if:

In non-structural areas (e.g., interior floors).

Stable (no widening over time).

Best for: Structural cracks (0.05–0.5 mm).

Steps:

Clean the crack (use compressed air or a wire brush).

Seal the surface with HM-9 epoxy putty (to prevent leakage).

Install injection ports (every 20–30 cm).

Inject low-viscosity epoxy (pressure: 0.1–0.3 MPa).

Cure for 24–48 hours.

✅ Pros: High strength, long-lasting.

❌ Cons: Requires skill; not for moving cracks.

Best for: Non-structural cracks (0.1–0.3 mm).

Steps:

Dampen the crack (prevents premature drying).

Apply slurry (acrylic-modified cement).

Smooth with a trowel.

✅ Pros: Easy DIY solution.

❌ Cons: Less durable than epoxy.

Best for: Multiple microcracks.

Materials: Silane/siloxane sealers.

Application: Spray or roll onto the surface.

Effect: Waterproofs without changing appearance.

✅ Pros: Prevents future damage.

❌ Cons: Doesn’t structurally repair cracks.

| Method | Lifespan | Best for |

Epoxy Injection | 10+ years | Structural cracks |

Penetrating Sealers | 5-8 years | Preventive sealing |

Polymer-Modified Slurr | 5-10 years | Surface repair |

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

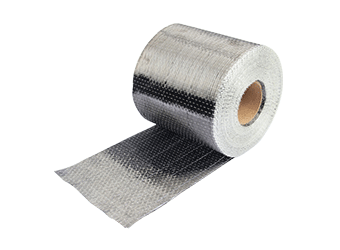

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack